Our Story

ARG is representing one of the world leaders in AIDC Technology, viz. a) TSC Auto ID , Printronix Auto ID, Kores India Ltd., Honeywell for Barcode Printers, Barcode Scanners, Portable Data; b) TYSSO Fametech America, Inc. Taiwan for Barcode Slot Readers I Magnetic Slot Readers etc. Thermal Transfer Ribbon jumbo rolls are being sourced from the best companies of Japan.

ARG is also representing some of the world leaders in Hand Labeling Technology for Price Marking Labelers and Sequential Labeling Machines from one of the best company i.e. Open Data SRL, ITALY.

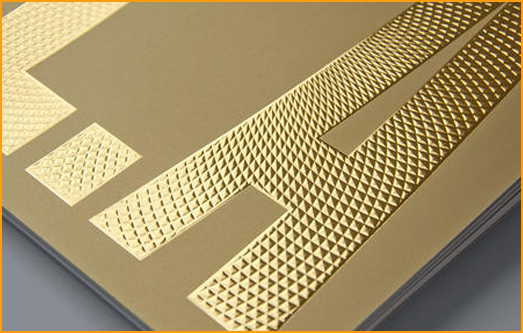

ARG is one of the leading manufacturers for Self Adhesive Labels and uses label stock (Raw Material) from world’s leading company Avery Dennison.

The ARG Label & Technology is part of Prakash Labels Pvt. Ltd., Noida – India introduces our self as one of the leading solution providers of Auto-Identification and Data Capturing Technologies. We are one of the largest manufacturers of Self Adhesive Labels (for Product Identification and Barcode etc.) and have in house Thermal Transfer Ribbons slitting facility. The ribbon slitting is being done on state of the art imported machines.

We set up our sales office and manufacturing unit in Emirates, at Ajman Free Zone in 1999 to have better co-ordination & sales services for our customers from these parts of the world. We are working with 15 to 20 countries like Egypt, Jordan, Kuwait, Qatar, Saudi Arabia, Oman, Bahrain, Mauritius, Madagascar, Kenya, Pakistan, Bangladesh, Sri Lanka, Ethiopia, Tanzania, Uganda, Vietnam, Indonesia etc.

ARG offer quality labelling solutions and services to diverse industry verticals all across UAE. The team of specialists have in-depth knowledge and expertise for offering innovative as well as comprehensive labelling solutions to fulfil specific customer needs. ARG focuses on a client-centric model which provides an optimum solution for enhancing the visual appeal, quality and ensuring the timely delivery of the labels.

Working to meet the label printing challenges of our clients to achieve continuous growth and establish strong customer relations.

An ISO certified company striving to deliver quality labels.

Providing high-quality labelling solutions aligned with the production schedules to ensure on time delivery.

Upgrading and implementing the emerging technologies to provide the best quality and cost-effective labels on time.

Working closely with customers to understand their specific needs and offer customised solution.

ARG deliver the best quality products to all of customers. All our products go through a strict quality control process. Our ISO certification is by TUV NORD.

ARG exhibits the ability to consistently provide products that meet customer and regulatory requirements. The core concepts of these labels include management, customer, requirements, policy, procedure, planning, performance, objective, control, monitoring, measurement, auditing, decision making, corrective action, and nonconformity. ARG satisfies the requirements mentioned in the ISO clauses and judiciously implements it to enhance customer satisfaction by meeting the customer requirements.

● The Automated Online Verification system at ARG eliminates defects in labels, produced.

● Our spotlessly clean plant maintains a dust-free environment, so that the labels that ARG provide to clients are of the highest quality.

● ARG is committed to continuous process improvement, defect prevention and the reduction of variances to achieve total customer satisfaction.

● High standards are maintained at ARG under the guidance of our Quality Assurance Managers, who oversee every aspect of the manufacturing process from design to order placement to delivery.

The 3M tape test is the most common test performed during a product inspection or pre-shipment inspection by the QC on the product label. The result is always shown in the inspection report. The standard is used to test the coating resistance. The test is performed in-site, at the factory by the QC team.

ARG uses machines to test the scuffing of printed materials. Scuffing usually occurs when there is friction between the two surfaces. This results in fading of the print due to abrasion of the film or paper. ARG takes precautions to avoid the scuffing when the label is put into real life working conditions.

ARG uses this test method to measure the peel adhesion or bond strength of the pressure sensitive labels. It is important to ensure that the labels are securely attached to the product. Adhesion bond strength can be measured in terms of the bonding and peeling strength.