In today’s hyper-competitive supply chain ecosystem, inventory visibility is no longer a back-office function — it is a strategic growth driver.

Warehouses, logistics companies, manufacturers, retailers, and cold storage operators are all facing rising operational pressure to improve:

- Inventory accuracy

- Order fulfillment speed

- Asset traceability

- Dispatch efficiency

- Warehouse productivity

- Loss prevention

- Automation readiness

Even a small tracking error can lead to stockouts, delayed shipments, or revenue leakage.

This is why one critical question dominates modern operations strategy:

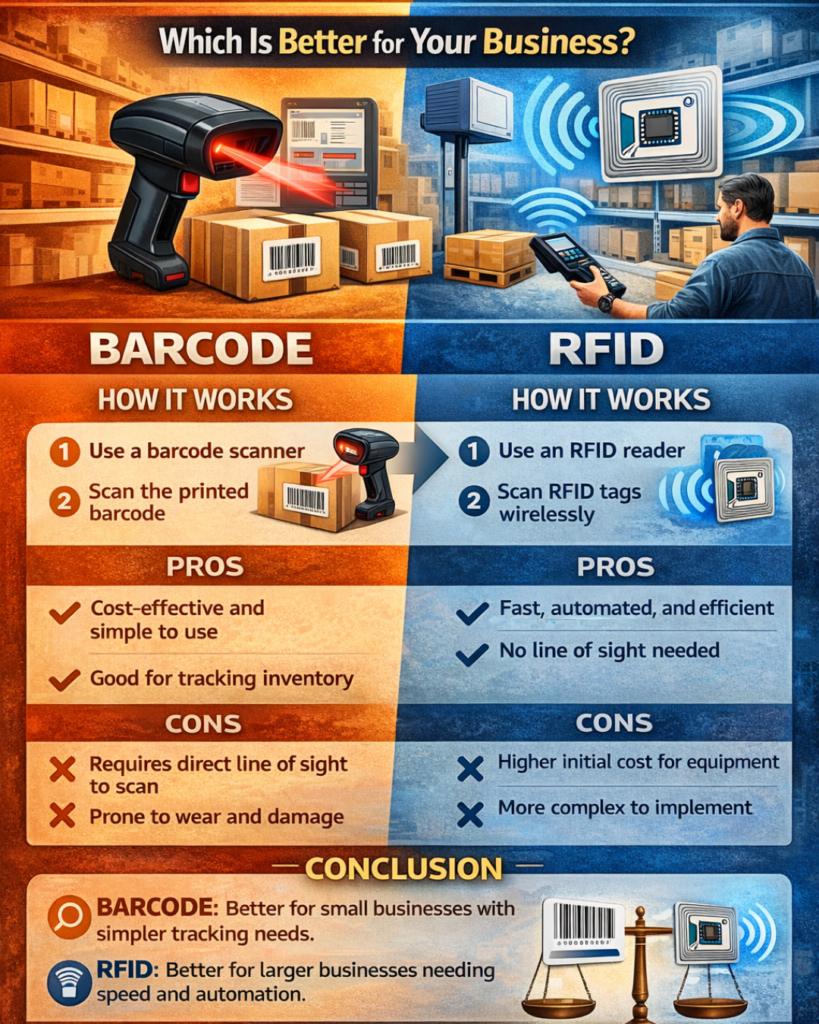

Should you continue with barcode systems, or upgrade to RFID tracking technology?

Both technologies serve the same core purpose — asset identification and inventory tracking — but their capabilities, costs, scalability, and automation potential differ significantly.

This in-depth guide compares barcode vs RFID across technology, cost, use cases, automation, and ROI — helping you make the right investment decision.

Understanding Barcode Technology

Barcode technology has been the backbone of inventory tracking for over 50 years.

A barcode label contains machine-readable information encoded in printed black bars and spaces. When scanned using a barcode scanner, the encoded data links to backend systems such as:

- Warehouse Management Systems (WMS)

- Enterprise Resource Planning (ERP) platforms

- Retail POS systems

The system then updates stock levels instantly.

Types of Barcodes

- 1D Barcodes — UPC, EAN, Code128

- 2D Barcodes — QR codes, DataMatrix

2D barcodes store more data but still require line-of-sight scanning.

Common Uses of Barcode Labeling

Barcode systems are widely used across industries:

- Retail billing & POS

- Warehouse inventory tracking

- Shipping & courier labeling

- Manufacturing production lines

- Document tracking

- Asset tagging

Barcodes are especially effective in structured, process-driven environments.

Advantages of Barcode Systems

- Low implementation cost

- Easy to deploy

- Minimal training required

- Globally standardized

- Works with legacy systems

- Affordable consumables

For SMEs or businesses beginning digitization, barcode is the most practical starting point.

Understanding RFID Technology

RFID (Radio Frequency Identification) is a next-generation tracking technology designed for automation and real-time visibility.

RFID tags contain embedded microchips that store asset data and transmit it via radio waves to RFID readers.

Unlike barcodes, RFID does not require visual scanning.

This means:

- Items can be scanned inside cartons

- Pallets can be tracked automatically

- Bulk inventory can be counted instantly

Components of RFID Systems

A complete RFID ecosystem includes:

- RFID Tags (Passive, Active, Semi-Passive)

- Fixed or Handheld RFID Readers

- Antennas

- RFID Portals / Dock Doors

- Middleware Software

- Cloud or On-Premise Database

Together, they create a real-time tracking infrastructure.

Common Uses of RFID

RFID is widely deployed in:

- Automated warehouses

- Apparel retail chains

- Pharmaceutical logistics

- Cold storage supply chains

- High-value asset tracking

- Airport baggage systems

RFID excels in high-volume, high-speed environments.

Barcode vs RFID — Technology Comparison

| Feature | Barcode | RFID |

| Scan method | Line-of-sight | Radio waves |

| Bulk scanning | Not possible | Yes |

| Scan speed | Moderate | Extremely fast |

| Automation level | Limited | Advanced |

| Human dependency | High | Low |

| Data storage | Limited | High |

| Real-time tracking | No | Yes |

Simplified View

- Barcode = Manual tracking

- RFID = Automated intelligence

Barcode vs RFID for Warehouse Management

Warehouse operations are where technology choice has the highest operational impact.

Barcode Works Best When:

- Warehouse size is small to mid-scale

- SKU volume is manageable

- Manual audits are acceptable

- Budget constraints exist

- Automation is not immediate

Barcode scanning is effective but labor-dependent.

RFID Works Best When:

- Warehouses are large or multi-location

- Real-time stock visibility is required

- Automation is planned

- Labor costs are high

- Inventory velocity is fast

RFID enables continuous, passive tracking without manual intervention.

Hybrid Deployment Strategy

Many enterprises combine both technologies:

- Barcode → Item-level labeling

- RFID → Pallet / bin / asset tracking

This balances cost and automation.

Cost Comparison — Barcode vs RFID

Cost is often the biggest decision driver.

Barcode System Cost

Typical investments include:

- Barcode labels

- Thermal printers

- Handheld scanners

- Software integration

Cost profile: Low upfront investment.

Consumables like labels are inexpensive, making barcodes budget-friendly.

RFID System Cost

RFID infrastructure requires:

- RFID tags (higher unit price)

- Fixed readers

- Handheld readers

- Antennas & portals

- Middleware software

- Installation & calibration

Cost profile: Medium to high upfront investment.

Long-Term ROI of RFID

Despite higher initial costs, RFID reduces operational expenses through:

- Labor cost savings

- Faster audits

- Fewer shipping errors

- Reduced shrinkage

- Automated compliance tracking

Large warehouses often achieve ROI within 12–24 months.

Inventory Accuracy Comparison

Inventory accuracy directly impacts profitability.

| Metric | Barcode | RFID |

| Inventory accuracy | 85–92% | 98–99% |

| Cycle counts | Manual | Automated |

| Audit frequency | Periodic | Continuous |

| Stock visibility | Delayed | Real-time |

RFID significantly reduces stock mismatches and order errors.

Cold Storage & Extreme Environment Performance

Cold storage logistics create labeling challenges.

Barcode Limitations in Freezers

- Adhesives fail in sub-zero temperatures

- Ink fades due to condensation

- Frost blocks scanner visibility

This leads to scanning failures.

RFID Advantages in Cold Chain

RFID tags are available in encapsulated formats that resist:

- Moisture

- Ice buildup

- Temperature extremes

- Chemical exposure

They enable scanning without visual contact — ideal for frozen goods and pharmaceuticals.

Role of RFID in Warehouse Automation

Automation is redefining supply chain efficiency.

RFID integrates with advanced systems such as:

- Conveyor tracking

- Automated sorting lines

- Robotic picking arms

- Smart dock doors

- IoT warehouse sensors

This creates a connected warehouse ecosystem.

Barcode systems support structured workflows but cannot enable full automation independently.

Compliance & Regulatory Tracking

Certain industries require strict traceability:

- Pharmaceuticals

- Aerospace

- Defense

- Food supply chains

RFID enables serialized tracking and automated compliance logging, improving recall management and audit readiness.

Future Trends — Inventory Tracking Beyond 2026

Businesses comparing barcode vs RFID are increasingly planning for future scalability.

Drone-Based RFID Stock Counting

Autonomous drones equipped with RFID readers scan inventory stored on high racks.

Benefits include:

- 90% faster audits

- Improved safety

- No manual lifting equipment

- Continuous stock monitoring

Blockchain-Enabled Asset Tracking

Blockchain integration with RFID creates immutable tracking logs.

Every asset movement is permanently recorded, ensuring:

- Anti-counterfeiting protection

- Supply chain transparency

- Regulatory compliance

Smart RFID Shelves

Smart shelves detect item placement and removal automatically.

They enable:

- Real-time stock updates

- Automated replenishment alerts

- Retail theft detection

AI-Powered RFID Analytics

AI tools analyze RFID data to:

- Forecast demand

- Detect shrinkage risks

- Optimize warehouse layouts

- Improve picking efficiency

This transforms tracking data into operational intelligence.

Industry Use Case Comparison

| Industry | Preferred Technology |

| Retail stores | Barcode |

| Apparel chains | RFID |

| Pharmaceuticals | Hybrid |

| Manufacturing | Barcode |

| Logistics hubs | RFID |

| Cold storage | RFID |

Technology adoption depends on scale, compliance, and automation maturity.

When Should You Upgrade from Barcode to RFID?

Businesses typically transition when they experience:

- Frequent stock mismatches

- Manual audit delays

- High labor dependency

- Asset misplacement

- Dispatch inaccuracies

- Warehouse expansion

As operations scale, barcode limitations become costlier than RFID investment.

Business Benefits of Implementing RFID

Organizations upgrading report measurable improvements:

- 10x faster inventory counts

- Real-time stock visibility

- Reduced manpower costs

- Improved order accuracy

- Lower shrinkage losses

- Faster dispatch processing

RFID enables predictive, data-driven warehouse management.

Challenges of RFID Implementation

To make this guide unbiased (and stronger than competitors), here are real considerations:

- Higher upfront investment

- Infrastructure setup time

- Signal interference (metal/liquid environments)

- Integration complexity

However, modern RFID solutions are designed to mitigate these challenges.

Barcode vs RFID — Final Verdict

There is no universal winner.

The right technology depends on operational complexity, automation goals, and budget.

Choose Barcode If:

- Budget is limited

- Operations are manual

- Warehouse scale is moderate

- Automation is not immediate

Choose RFID If:

- Automation is the priority

- Real-time tracking is required

- Warehouse scale is large

- Accuracy is mission-critical

- Labor optimization is needed

Best Practice: Hybrid Ecosystem

Most enterprises deploy a combination:

- Barcode for SKU labeling

- RFID for pallets, assets, and automation

This balances cost and scalability.

Looking to Implement Barcode or RFID?

Selecting the right tracking technology is not just an IT decision — it’s an operational transformation strategy.

We help businesses implement:

- Barcode labeling systems

- RFID tagging solutions

- Warehouse automation infrastructure

- Cold storage labeling solutions

- Asset tracking platforms

Get a Free Consultation

Planning to upgrade your inventory tracking system?

Our specialists assist with:

- Requirement assessment

- Technology selection

- Cost comparison

- ROI forecasting

- Implementation roadmap

Connect with us today to build a smarter, automated, error-free warehouse ecosystem.